The process is used for mostly large objects or when the number of parts produced is small. Thus requiring the proper.

Cold Forging Understanding The Process And Some Key Calculations Engineering360

Forging is the process in which metal cold or heated is shaped into a component geometry.

. Determining the position of the parting line is a critical step in. Example a real life design of clutch release fork has been taken and an attempt has been made to design Die set. Determine radial and tangential stresses in one ring two ring and three ring die assemblies with press fit and internal forging pressure.

Here forging die is implemented efficiently low cost manufacturing again seeFigs. This includes tensile strength yield strength ductility and impact toughness. PScrew press tonnage KN.

There is a ram or hydraulic press that shapes the hot bulk metal into desired shapes. Draft angles between 3 degree and 10 degree are normally provided for easy ejection of forging. Introduction to Forging 4 hr s Various processes of forging examples of components.

Open-die forging operations are applied in an open environment with several workforces. Also referred to as the free forging. For aluminium alloys it is from 400 to 450.

Ejectors ejector return mechanism die lubricants basic calculations mould release agents. Forging Manufacturing and Design Forging Die Mechanical Tolerances. Forging is the working of metal into a useful.

- p2bwk1b4t2 Where bwidth of die wwidth of work kshear flow stress. Ad Custom rectangle bars in ferrous non-ferrous materials. Part weights from 1 lb to 100000 lbs.

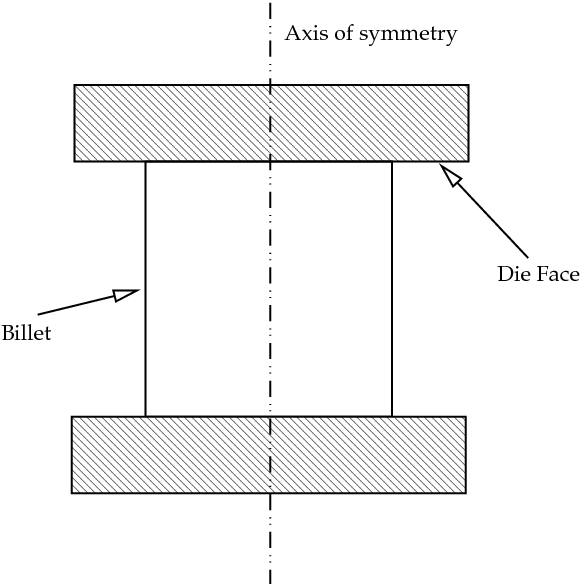

This fee includes class materials. The forging pressure required was assumed to be 30 tons per square inch of the area of the item to be forged about equivalent to 42 kgsq. Open-die forging Open-die forging is carried out between flat dies or dies of very simple shape.

The forging design is not a simple task. There are infinite combinations of various factors possible such as properties of material being forged type of forging process the tool design. Further working by closed-die forging modifies and refines the starting-billet grain structure to produce the best combination of properties in all test directions.

Ad Custom rectangle bars in ferrous non-ferrous materials. In this metal forging metal is subjected to a compressive force without being confined within dies. Forging die design and Forging defects NPTEL.

Open die drop forging. Commonly for ferrous alloys a forging temperature of 900 to 1200. Forging Counter die lock Simulation Die Design Clutch Release.

Tuition for Theory Applications of Forging Die Design is 1399 per student for FIA member organizations or 1999 for non-member organizations. Where material properties are critical it is important to specify the required properties in all directions. Of Multiple Connecting Rods.

C E Megharaj P M Nagaraj and K Jeelan Pasha. Part weights from 1 lb to 100000 lbs. Replacement of machinery occurred.

The oldest of the metalworking arts primitive. Handbook of Die Design Second Edition AccessEngineering. Department of Industrial Engineering and Manag.

Forging temperature decides the type of die material for forging. The die design such that forging hammer can manufacture more than one connecting rod in a given forging cycle time. Because the die is exposed to high loads.

727 and 728 compared with the traditional remanufacturing technology material saving. Shape by hammering or pressing. A precision forging die of an asymmetric spur gear was designed and the design criteria were presented.

Most forged parts require. The mating surfaces of the two halves of the die define a parting line around the edges of the forging as they come together. Design and Analysis of a Forging Die for Manufacturing.

4 4 FINITE ELEMENT CALCULATION 71 441 INPUT DATA 71 4 4 2 ASSEMBLY OF THE STIFFNESS EQUATIONS 73 4 4 21 STIFF SUBROUTINE 74 4 4 2 2 STRMTX SUBROUTINE 74. FORGING DIE DESIGN CALCULATIONS. Corner radii are to be larger as far as possible to facilitate smooth flow of material.

STRECON technology is one of the world-wide manufacturer who dealing with forging die and their recent design is claimed to be extended up to 10 times of the common design of die and. Sheet metal operations 8b Drawing Tools. 2k1b4t2 Average pressure under the dies t1.

To modify the die design study is carried out to understand the. However finite element. The calculation formula for selecting the tonnage of the screw press is as follows.

Schematic Design Of The Forging Process For A Hollow Part With A Download Scientific Diagram

Roller Detent Mechanism Design Equations And Calculator

Irrigations Systems Swimming Pool Design And Water Supply Systems Design Calculations By Sesinando Tibule Swimming Pool Designs Pool Designs Swimming Pools

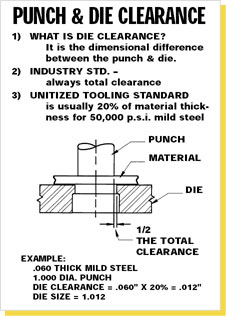

Die Clearance Calculator Die Clearance For Punching Steel Unipunch

Forging 02 Open Die Forging Youtube

Http Dcknives Com Public Grind Angle Php Knife Making Knife Making Tools Knife

Schematic Design Of The Die Forging Process For A Hollow Ball A Download Scientific Diagram

0 comments

Post a Comment